Qual-Pro is committed to providing our customers with the highest quality service throughout the value stream. We have assembled a team of experts, that as a group, have decades of experience in all aspects of EMS. From supply chain and logistics, design for excellence, manufacturing and test, process qualification, FDA and FAA submittals to product realization, we work with our partners to ensure success for our customer.

Our engineering group stays current with industry trends by

attending local and national conferences. We conduct technology road maps with

customers ensuring we capture future requirements and thus optimize the investment

in capital equipment.

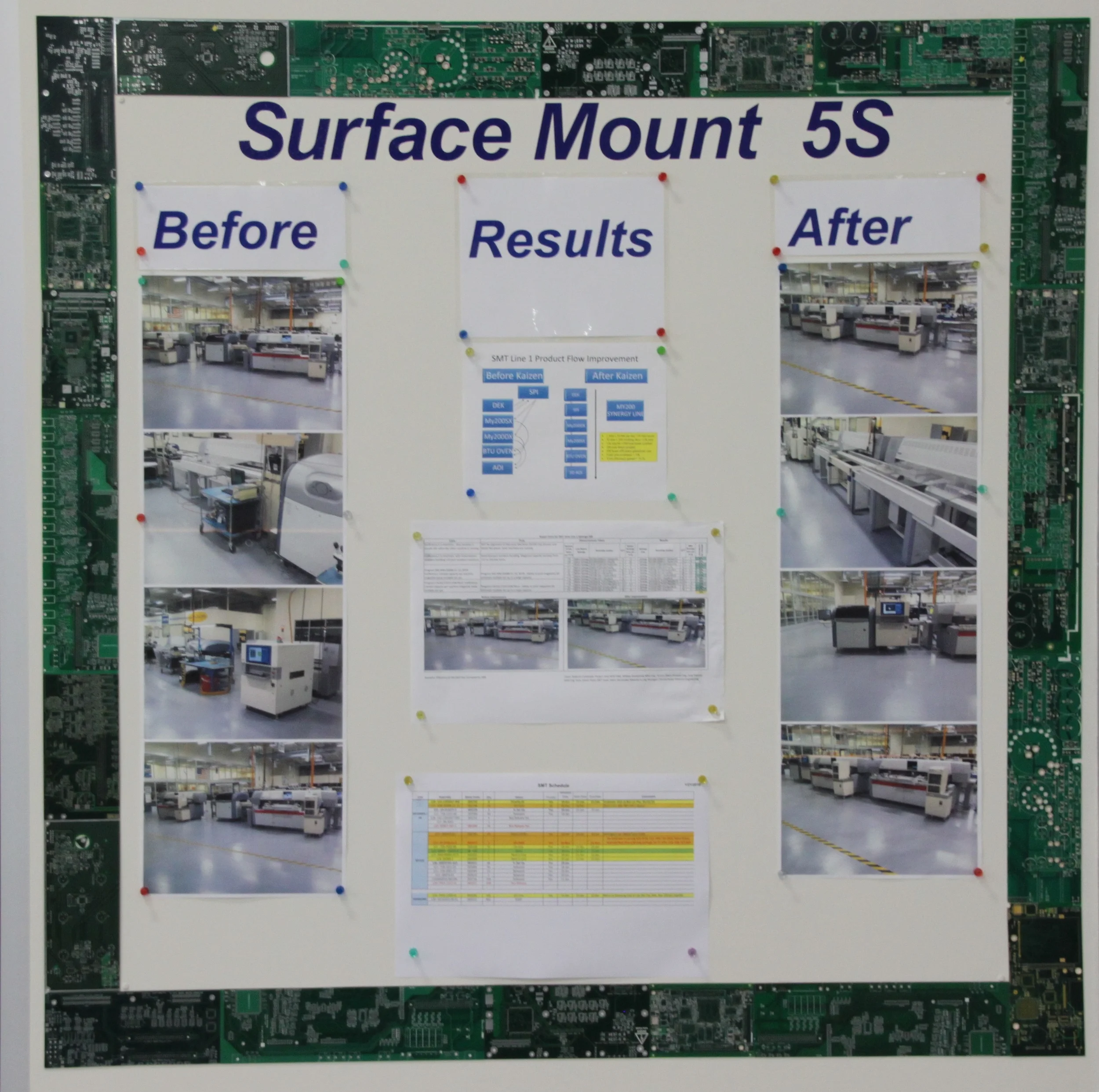

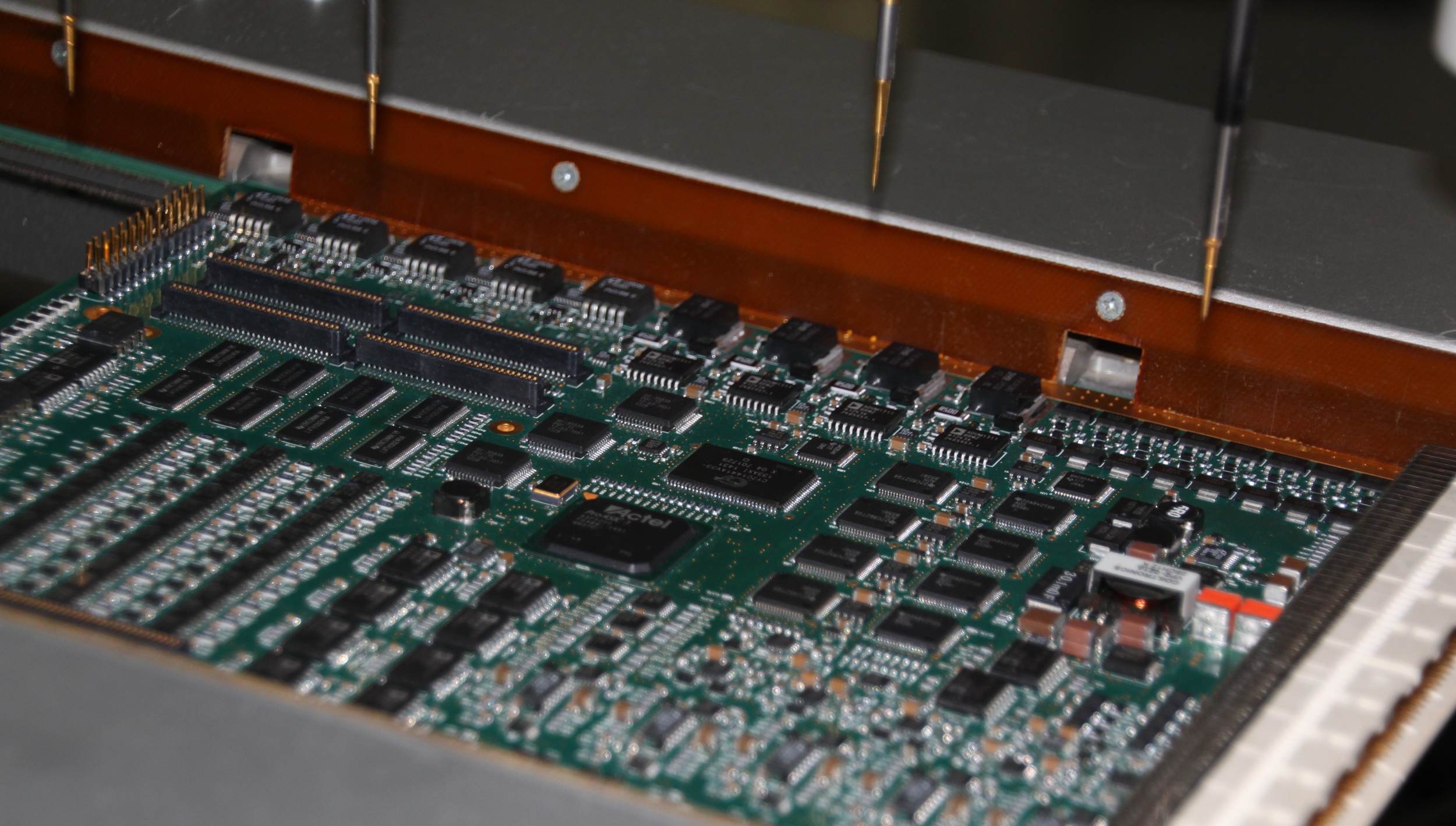

Our manufacturing group operates to IPC-A-610 Class 2, Class

3 and NASA standards.

The current equipment sets provide the following

capabilities:

- Lead and RoHS assembly

- Surface mount placement speeds up to 60,000 components

per hour (cph)

- Placement capability down to 01005

- BGA, µBGA and fine pitch assembly

- POP, package on package

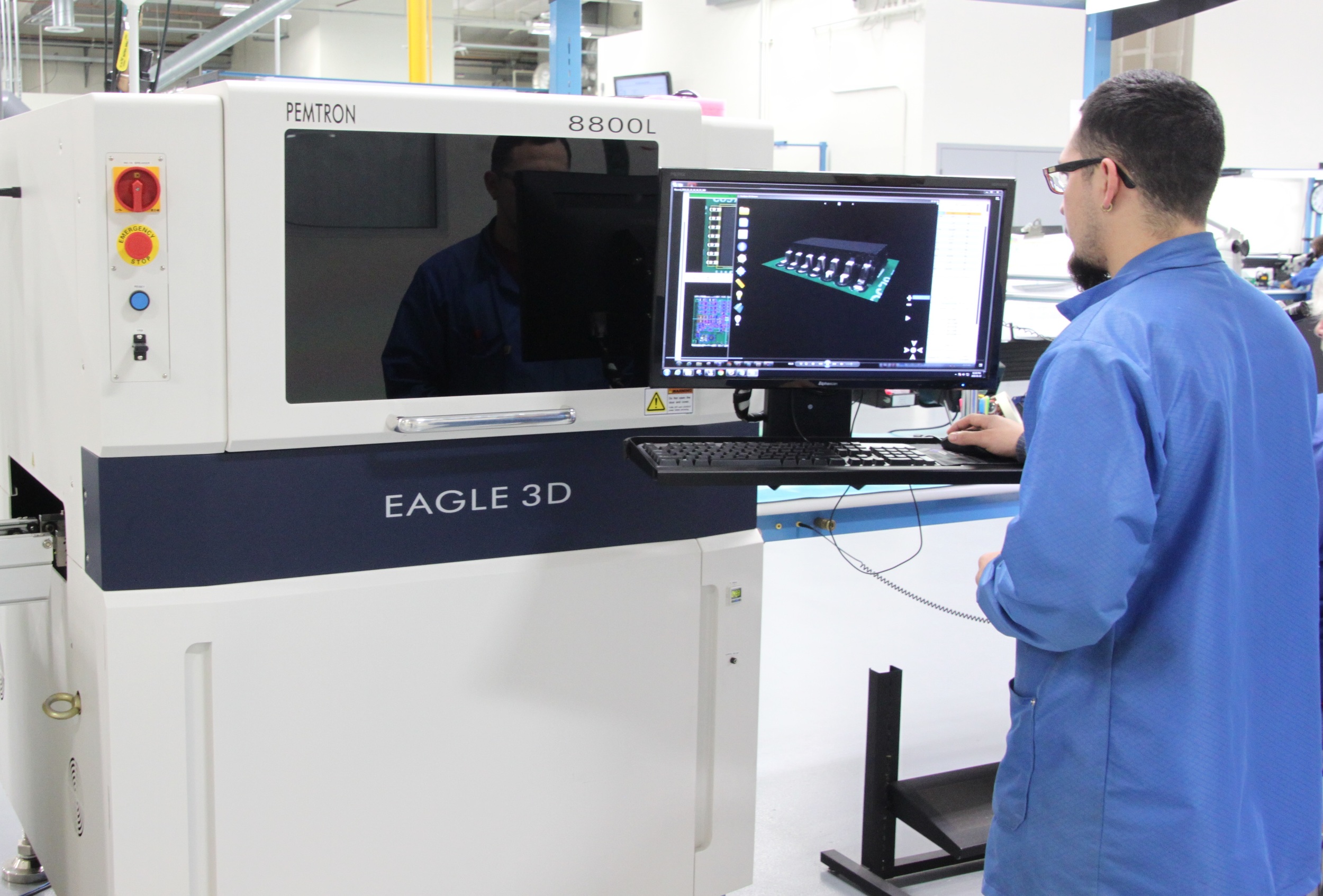

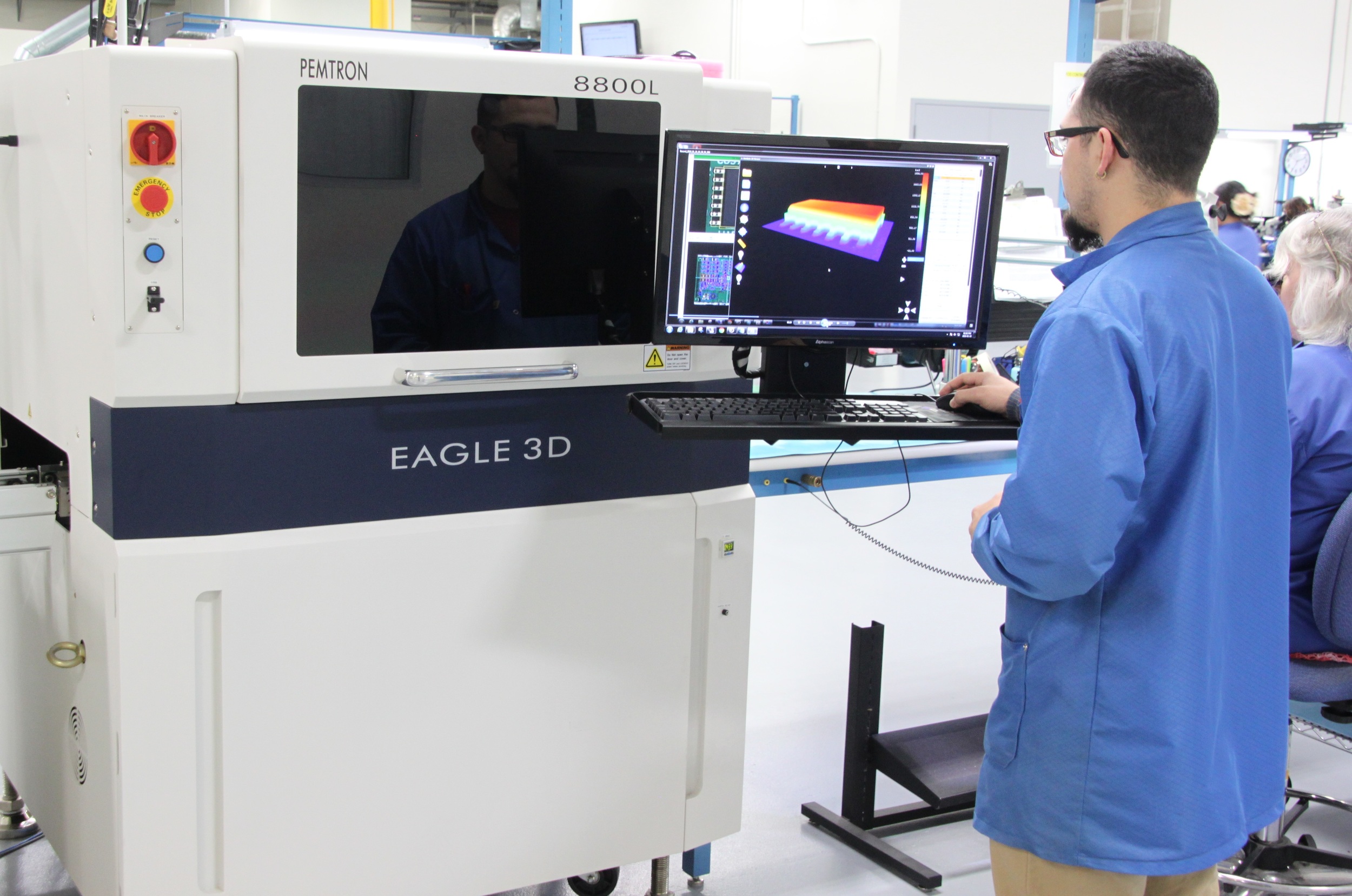

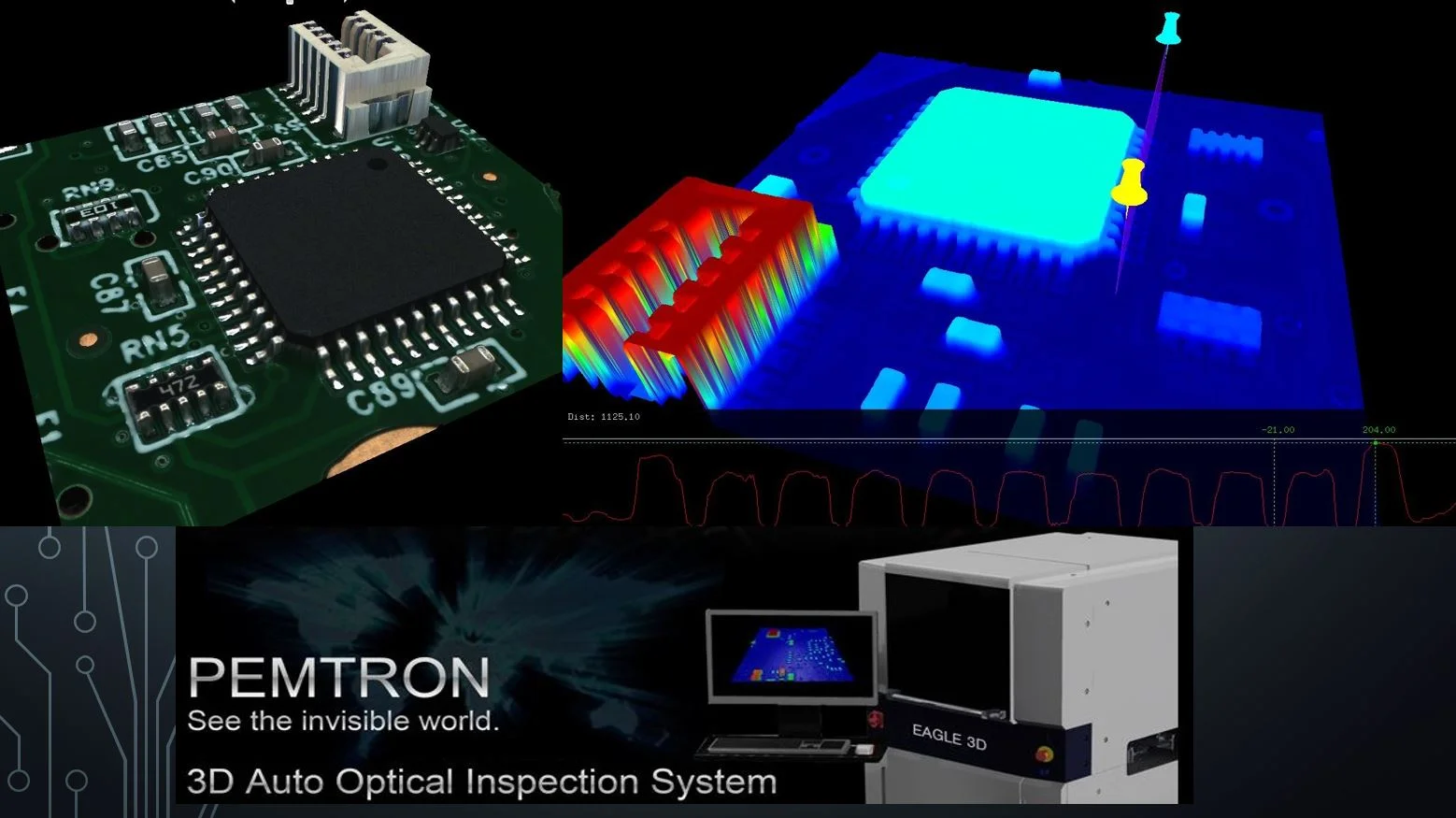

- 3D automated optical inspection

- 3D screen print inspection

- X-ray inspection

- Flying probe and benchtop testing

- Automated conformal coating, urethane and acrylic

deposition

- HLA (Higher level Assembly) and full integration